Experts in Vacuum Forming, CNC Trimming & Plastic Fabrication

Grab a quote today for your plastic project. No matter how big or small, how easy or hard our experienced product development managers will be able to exceed your expectations. We offer a diverse range of plastic services offering products for a number of industries including: point of sale displays, industrial products and components, medical devices, packaging, transport and automotive, recreation, mining and construction and everything in between!

Our Services

Vacuum Forming

Vacuum forming is a moulding process that involves heating sheet plastic into a three-dimensional component.

CNC Trimming

After a part has been formed it can go onto one of our CNC 5 axis machines which can cut an array of details into the part. Our 3 Axis CNC machine is ideal for cutting and engraving flat plastic sheet as well as an array of other materials like aluminium and timber.

Fabrication & Assembly

After parts have been vacuum formed or CNC trimmed there are a number of auxiliary fabrication services that are often required to pull your product together.

Point of Sale Displays

Successful point of sale also known as point of purchase displays starts with a good vision.

Distortion Printing

Our distortion printing process developed in-house called Print ‘N’ Form™ offers a whole new dimension to vacuum forming.

Signage

Warringah Plastics offers a wide variety of signage solutions which can help your message pop out from the crowd with creative 3D effects.

Industrial Design

At Warringah Plastics we invest heavily into design and we understand the difference between delivering a successful point of sale display isn’t just about cost but it’s all about quality; as the difference between good and bad design can make or break a product launch.

Project Management

Our team of account and product development managers can guide product from product design all the way through to delivery. Or alternatively bring your design to us and we can make it come to life.

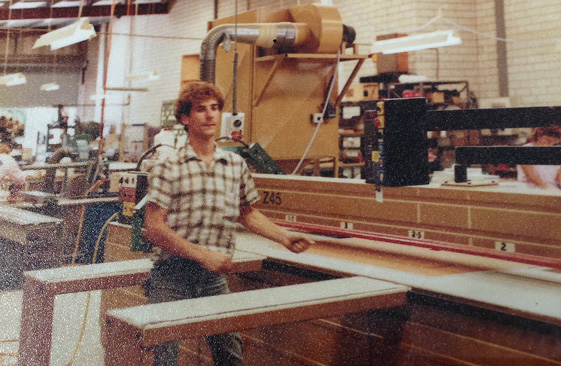

The World's best trust Warringah Plastics

We pride ourselves on providing the best possible customer service to our customers. With a personal touch, we understand the importance of providing responsive and valuable support which is why our customers trust and enjoy working with Warringah Plastics. Warringah Plastics is large enough to handle large and complex projects, yet we are flexible enough to provide fast turn around times on prototypes and urgent production jobs. Warringah Plastics is 100% Australian owned and operated so we can manufacture products in a timely manner and because of our well-developed systems and experience it doesn’t mean you have to pay a premium for this service.

Our project managers have years and years of industry experience and are formally qualified and trained. Our project managers can provide a full turn-key solution from concept ideation through to product delivery. Our award-winning designers understand the importance of branding and product differentiation so we can ensure your product stands out and doesn’t stick out.

We also pride ourselves on quality. Quality is one of the main focal points of our production facilities. Warringah Plastics has a unique approach to manufacturing and quality garnishing influence from some of the World’s most advanced manufacturing systems and philosophies. This approach ensures total quality solutions to our customers from aesthetic finishes, dimensional accuracy and functionality. However quality goes far beyond our manufacturing capabilities, it touches every facet of our business including customer care. Utilising the Japanese process of Kaizen (or continuous improvement) we are always listening to our customers needs and exploring new ways of working and partnering together.

Warringah Plastics is a an ISO 9001 Certified Company

Quality is at the centre of everything we do at Warringah Plastics. We strive to not only create products that are beyond your expectations, but also meet our high internal standards which comply with the ISO 9001 quality standard.

We take pride in not only in producing innovative products for market but also harbouring a culture of continuous improvement. Warringah Plastics is an ISO 9001 certified company that aims to deliver products that go above and beyond customer expectations. With our system-orientated environment we understand quality in a holistic way. This includes paying attention to designing, developing and manufacturing products fit for purpose and suitable for their environment. It also means producing products in a work environment that is clean, safe and reduces environmental impact. We also take great care in protecting data and information that belongs to our customers, suppliers and staff.

- A close up image of the fabrication job which involved making giant cans.

- Distortion printing and printing on plastic with a range of colours and shapes available made to order.

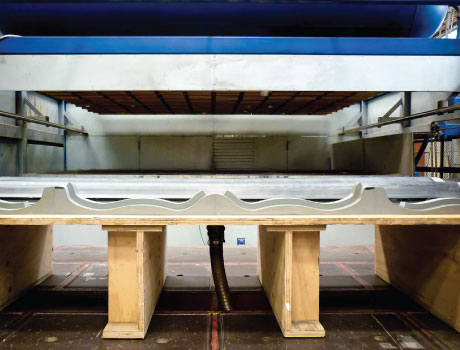

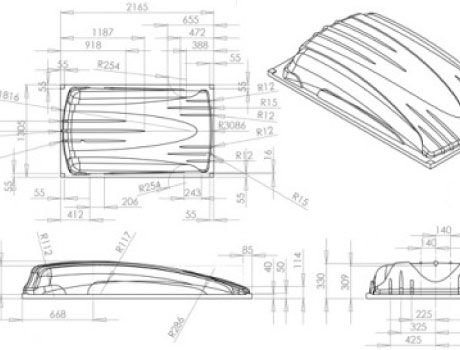

- Thermoformed Plastic Trailer Cover – Protect your cargo with this stylish design